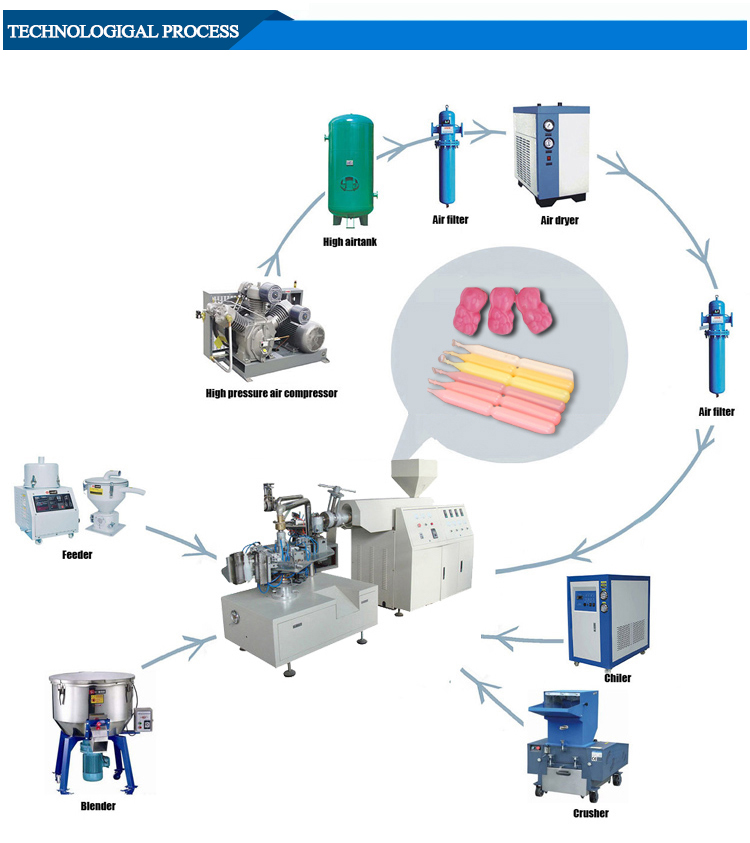

This machine is mainly suitable for plastic package with being blown up from side, such as the plastic bottles for eye-drop, fruit juice, milk, medicine, cosmetic etc. The machine adopts screw extruding blow molding technology in its extruder. And it is adopted auto-control temperature and FM activator. The machine is combined with electro motion, pneumatic power and mechanism. The main character of this machine is its simplicity & stabilization of operation. It has been famous for its excellent performance, low maintenance ratio, less consumption of electricity & low noise. May match according to the correlation product this aircraft truncates the mouth equipment automatically.

Technical parameter | GYJ-1 | GYJ-2 | GYJ-3 |

Equipment composition | 4-working-position blow machine with 45 extruder machine | 6-working-position blow machine with 55 extruder machine | 8-working-position blow machine with 65 extruder machine |

Max volume of the product ml | 800 | 1200 | 1500 |

Max diameter of the product mm | 80 | 100 | 110 |

Mould dimension ( L* W * H ) mm | 120×118×300 | 120×118×300 | 120×118×300 |

Production capacity PCS / day | 15000-80000 | 20000-120000 | 20000-160000 |

Gas consumption quantity m3 / min | 0.4 | ||

Screw diameter mm | 45 | 55 | 65 |

Long radius rate | 25:01:00 | ||

Plasticizing capacity kg / h | 25 | 40 | 60 |

Electric machinery power kw | 5.5 | 7.5 | 11 |

Total power kw | 14 | 17 | 22 |

Weight kg | 1500 | 1800 | 2000 |

Appearance dimension ( L * W * H ) mm | 3000×1200×1500 | 3300×1200×1500 | 3400×1300×1600 |

The suitable raw material | PE / PP / PS / PVC | ||

The method of adjusting the speed | Frequency conversion |