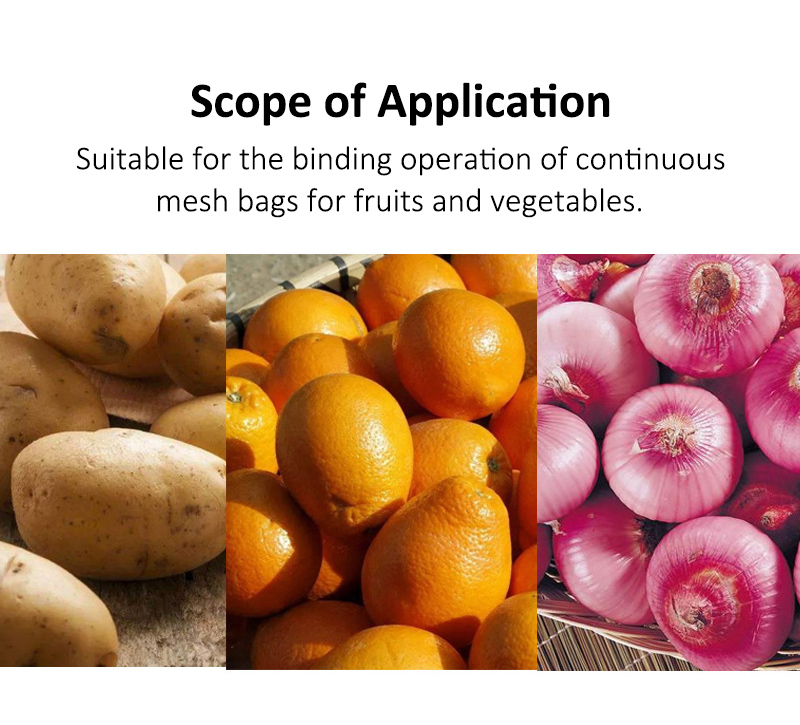

Full-automatic Mesh Bag Packing Machine

Introduction:

The unit speed of the bagged packaging equipment can reach 40 bags/minute at the fastest (the packaging speed of different products is different, and the actual number of packages shall prevail).

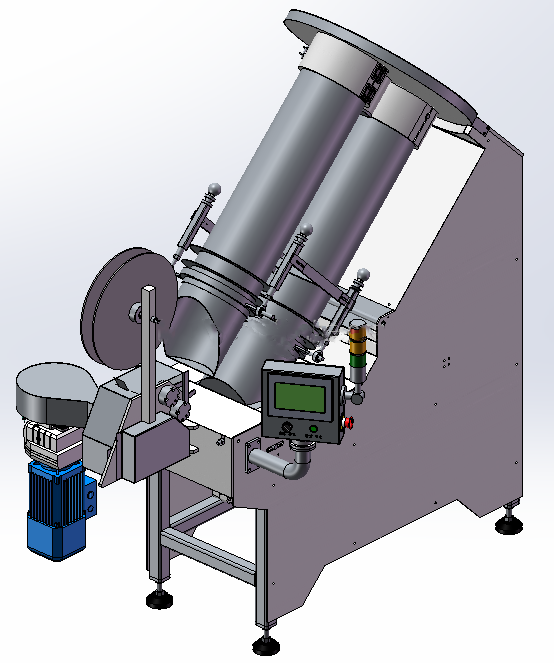

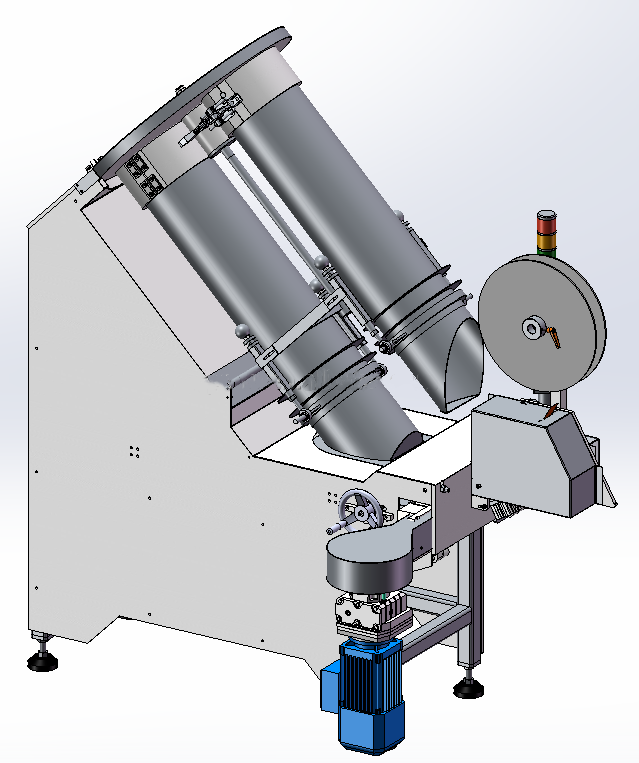

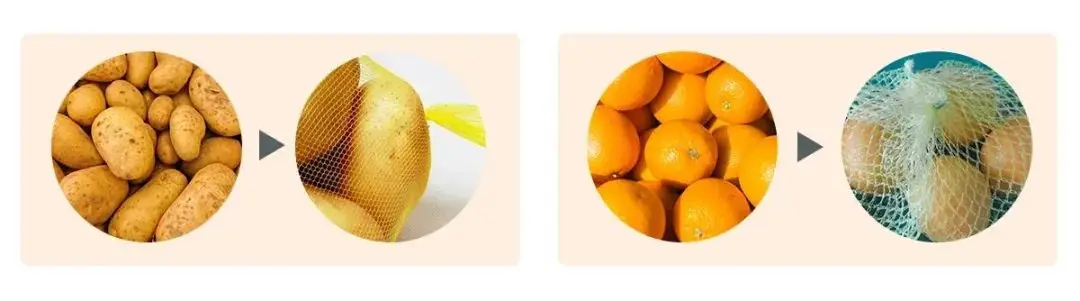

Working Process:

The work flow is as follows: After the manual sorting of products, the conveyor belt where the materials are placed in the middle is sent to the net bag packing machine by the lift conveyor belt, and the set label is automatically printed when the automatic packaging is completed. The manual framing is performed to complete the standardized packaging of products.

Features:

1. The machine is made of hard carbon steel plate and stainless steel, which is safe and sanitary, greatly improving the corrosion resistance of the equipment.

2. Automatically replace the network management after using the packing net.

3. AirTEC pneumatic components with stable performance and long service life are adopted.

4. The combination of two positioning gears and proximity switches makes the push net precise.

Advantage:

1. LS frequency converter with reliable performance and convenient operation, Schneider PLC and touch screen electrical control are adopted.

2. The package size is standard.

3. It is convenient and quick to replace the binding band.

4. The operation interface is popular, simple and convenient.

Parameter:

| Packaging speed | 40bag/min |

| Packaging materials | sausage, edamame, garlic, onion, potato, sweet potato, and other root type anti drop products |

| Weight | 500KG |

| Power supply requirements | 380V |

| Weight of package | 150g - 1500g |

| Applicable packaging material | net bag |